Introduction to Non-Woven Bags

In today's eco-conscious market, plastic non-woven bags have emerged as the sustainable alternative to traditional plastic bags. As a leading manufacturer, Castalia International Pte Ltd specializes in high-quality non-woven polypropylene bags that combine durability with environmental responsibility.

This comprehensive guide covers:

What Are Non-Woven Bags?

Definition & Composition

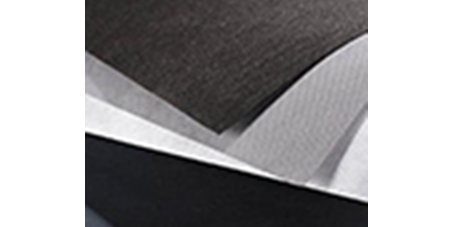

Non-woven bags are made from polypropylene (PP) fibers bonded together through:

Unlike woven fabrics, they don't require yarn spinning or weaving.

Material Properties

Manufacturing Process

Step-by-Step Production

Types of Non-Woven Bags

|

Type |

Characteristics |

Common Uses |

|

Spunbond |

Lightweight, breathable |

Shopping totes |

|

SMS |

3-layer (Spunbond-Meltblown-Spunbond) |

Medical packaging |

|

Laminated |

Waterproof surface |

Promotional bags |

|

Reinforced |

Fabric handles |

Heavy-duty carrying |

Key Benefits

1. Environmental Advantages

2. Commercial Benefits

3. Functional Properties

Customization Options

Design Flexibility

Size Specifications

|

Size (cm) |

Capacity |

Best For |

|

30×40 |

10-15kg |

Groceries |

|

40×50 |

15-20kg |

Shopping |

|

50×60 |

20-30kg |

Promotional |

Sustainability Comparison

Key Findings:

Industry Applications

Retail Sector

Healthcare Uses

Other Applications

Quality Standards

International Certifications

Performance Testing

Why Choose Castalia International?

Manufacturing Advantages

Custom Solutions

Sustainability Commitment

Buyer's Guide: Selecting Your Supplier

6 Critical Factors

Frequently Asked Questions

Q: How many times can non-woven bags be reused?

A: Quality bags withstand 50+ washes when properly cared for.

Q: Are these bags waterproof?

A: Standard versions are water-resistant; laminated options provide full waterproofing.

Q: What's the minimum order quantity?

A: We accept orders from 1,000 pieces with no maximum limit.

Q: Can you match existing bag designs?

A: Yes, we can replicate any design with potential improvements.

Q: How long does production take?

A: Standard lead time is 15-20 days; expedited 7-day service available.

Market Trends & Future Outlook

Growing Demand Drivers

Innovation Frontiers

Conclusion

Non-woven polypropylene bags represent the perfect balance between functionality, economy, and environmental responsibility. As governments worldwide implement stricter plastic regulations, these versatile carriers offer businesses a sustainable packaging solution that aligns with modern ecological standards.

Castalia International Pte Ltd provides:

Contact us today for samples or quotes:

email : info@castalia-international.sg and enquiry@castalia-international.sg

website : www.castalia-international.sg

Upgrade your packaging with sustainable non-woven solutions from an industry leader. Partner with Castalia International for quality you can trust.